Tanks

The piping and various tanks related to steam and condensate transfer always depend on the processes using steam as the heating medium.The processes can be quite different, but the related steam and condensate systems are similar regardless of the size of the plant; naturally, the power required, operating pressures, and equipment used vary depending on the application requirements.

Steam is produced according to the application in units ranging from small steam generators and steam boilers to large power plant boilers, from which it is supplied after different stages through piping to smaller consumers.

The water fed into steam boilers is treated and the removal of oxygen and other non-condensable gases arranged at the boiler plant. However, air and non-condensable gases can still accumulate in steam and condensate systems as a consequence of process variations and deficient water treatment. Taking care of deaeration is of great importance, since gases prevent efficient heat transfer and induce corrosion. For tank and steam piping deaeration, sensitive thermal steam traps can be used.

Saturated or, if the application is farther away, superheated steam is fed via transfer piping to consumers, in which the heat contained in steam is transferred over a heat exchanger, for example, to the process. After this, the steam converted to condensate is returned to the boiler plant for re-vaporisation.

Our product range includes an excellent comprehensive choice of equipment and assemblies for process management. In addition to mechanical devices, we supply control valves and automation equipment for accurate process control. The boiler plant equipment in our product range is based on the boiler automation technology of the German company Gestra.

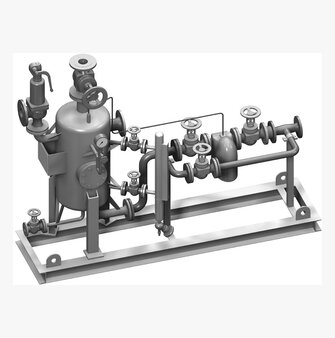

In addition to tanks, systems need various auxiliary equipment such as shut-off, control and non-return valves, sludge separators, level controllers, etc. for efficient operation. In co-operation with the customer, we will choose the components most suitable for the process, equip the tank, and carry out the final inspection of the system. On agreement, we can also participate in system commissioning at the customer’s site.